EXPERTS ON THE ROAD

Innovation is not instantaneous — innovative development requires a long-term approach and commitment. One way to inspire innovation is through collaboration, both inside a company’s network as well as outside. In this way, we ensure products not only meet, but also exceed both current and future demands of the end user.

INDUSTRY WORKSHOP

Emsland Group experts joined industry professionals at the Healy Group Workshop in Leicestershire, UK.

A special focus of the workshop included the topic of clean label food ingredients. Consumers and the ever-growing influence of social media are drivers of the clean label product trend. This is a demand that we, as ingredient producers, must meet in order to give our customers the flexibility of labeling their products as “Clean Label”.

Cindy Semeijn, Head of Business Development and Marketing, and Heidrun Lambers, Head of Food Application at the Emsland Group, gave a presentation on the Emsland Group’s clean label product line ‘Empure’. They showed how this product line, together with other clean label products, such as pea and potato fibers and pea protein isolates, could be used for concepts in different food segments. During discussions with attendees, they observed that there is a clear need for a solid definition of what clean label is:

E-number free, transparency and easily recognizable ingredients are mentioned, but also food that is less processed falls under the definition. Especially ultra-processed food is under a lot of pressure in the UK as these products are recognized as unhealthy. Social media plays an important role in the popularity of clean label foods and the further demonization of ultra-processed food.

TECHNICAL WEBINAR

Application Engineer Anna Schultz teamed up with the agency Haarla Oy to host a webinar on the topic of dairy alternative products.

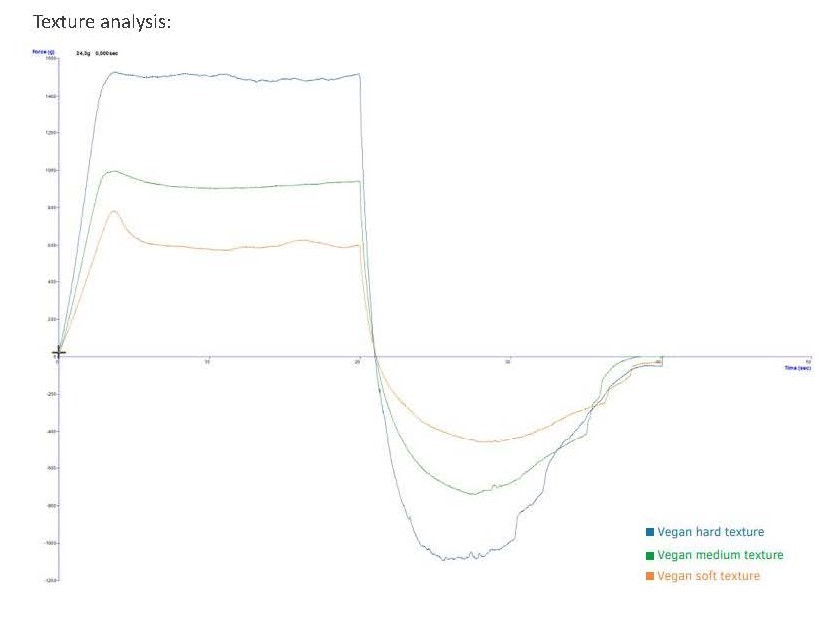

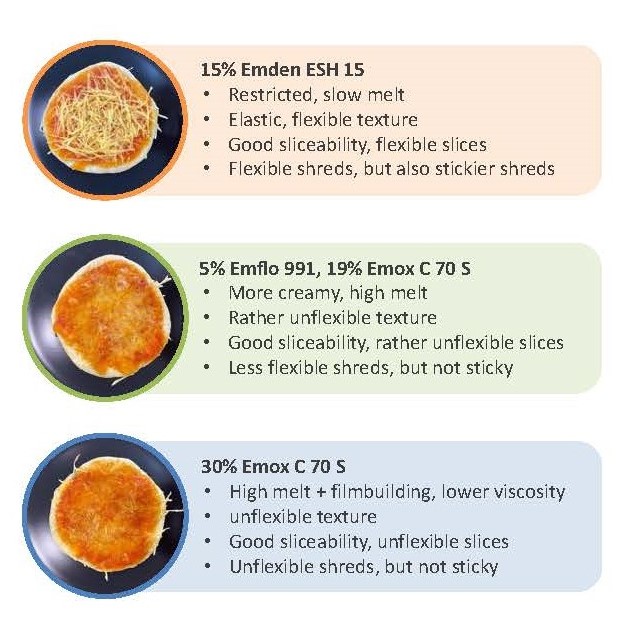

In the webinar, the experts took a closer look into the role that modified starches and pea protein isolates can have in producing dairy alternatives. For example, gelling, thickening and emulsifying starches can influence processed and vegan cheese characteristics, including shelf life, creaminess and melting properties, shredability and sliceability, and gelation time.

Further concepts for texture variation in vegan cheese production can be seen below:

View the webinar recording.

Learn more about our solutions for the dairy alternatives market.