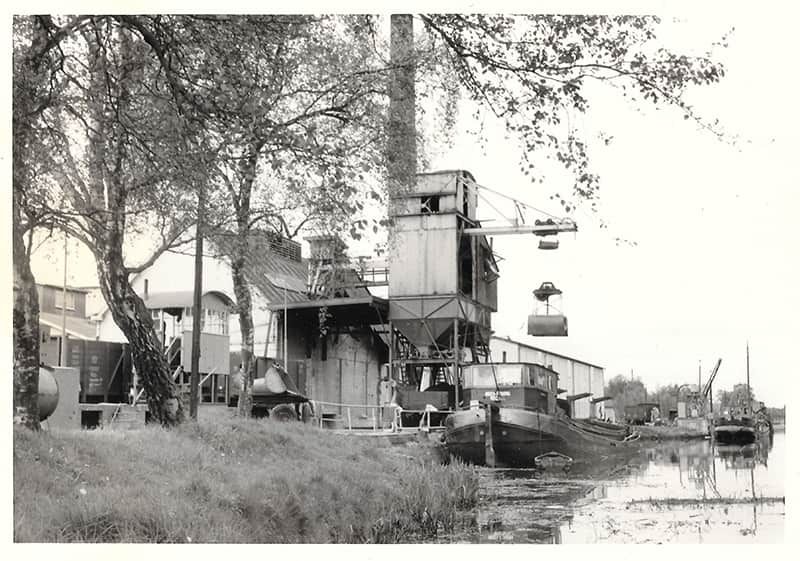

Our roots

Using nature to create

We are a down-to-earth group of companies with a very close relationship to our owners. Our raw material procurement and production are closely linked to our region. At the same time, we market our products worldwide so that our sales and supply chain are highly international. The ideal combination of a local producer and a worldwide marketer in an international, medium-sized group of companies with group structures is our competence and constant challenge.

Company Policy

All business activities are characterized by a strong customer orientation. Our ambition is to meet the specific requirements, needs and expectations of customers, contract farmers, shareholders and, in particular, our employees and other interested parties associated with us. By providing the necessary resources, we ensure the company’s success by constantly improving our business processes, quality, environmental protection, energy efficiency and health+safety.

The optimization potential of our business processes is continuously monitored and supported by integrated processes and systems. Compliance with all legal regulations relevant to us is just as firmly anchored in our actions as the guarantee of product safety and hygiene of our food and feedstuffs and the excellent quality of all products manufactured. We are aware of our responsibility as part of the food and feed chain and promote food and feed safety culture at all levels.

Conservation of resources, continuous minimization and prevention of environmental pollution as well as occupational health and safety are equally important. We encourage our suppliers to use their services in a energy-efficient manner and to supply products that are economical in terms of energy consumption. Stakeholders are adequately informed about the relevant business processes. The necessary data is provided on the Internet or intranet. The conservation of resources, the continuous minimization and prevention of environmental pollution as well as occupational health and safety are just as important.

We use our integrated management system for quality, safety, health, energy and the environment as an instrument for the continuous improvement of all our services and activities along the value chain. A well-trained, highly motivated team of employees makes a significant contribution to achieving our goals and thus to the success of the entire company.

Mission

Our mission is to create innovative and high-quality products for our customers through renewable raw materials in a way that is in harmony with nature. We fulfill this task by living up to our motto “using nature to create” on a daily basis.

Vision

As a strong and competent marketing partner for contract farmers and shareholders, we guarantee reliable and sustainable value creation from potatoes and peas.

Founding of Emlichheimer Kartoffelfabrik AG

Initial production of potato starch and dextrin products begins.

Modernization of the starch and dextrin factories / Renamed to Emsland-Stärke Hunekuhl & Co. KG

In the 1940s and 50s, the starch and dextrin factories continue to be modernized and were renamed Emsland-Stärke Hunekuhl & Co. KG. In addition to potato flour and dextrins, glucose, dry potato pulp and special starches are produced.

Production increases and exceeds the 100,000-ton threshold

In the coming years, the company invests heavily in the Emlichheim site and the factory experiences enormous increases in production. In 1967, the quantity of potatoes processed exceeds the 100,000-ton threshold.

Acquisition of three potato starch factories in Germany

Until the early 90s, the Emsland-Stärke GmbH acquired over three potato starch factories in Germany, where increases in production and considerably improved starch quality were made possible and water consumption was also reduced.

New investments such as a new GIG-evaporation system follow. The Golßener Stärkefabrik GmbH, Kyritzer Stärke GmbH and Nordstärke GmbH subsidiaries merge in 1997 to form the Emsland-Stärke GmbH.

The first partnerships were established abroad to be able to continue to compete as a leader internationally.

Expansion of the areas of expertise

On April 01 2000, Emsland-Stärke took over the production as well as the distribution of potato flakes and granules for the industrial customers of CPC Bestfoods Deutschland, whereupon Emsland Food was newly established.

Emsland-Stärke was able to expand its offerings through the acquisition.As a result, Emsland-Stärke became the sole supplier of the three products potato starch, potato flakes and potato granules and was able to meet customer requirements even more strongly than before. The other areas of application in the starch industry also underwent continuous improvements. This led to Emsland-Stärke winning the textile prize for the best products and services in 2000.

With its increasing demands on quality and hygiene, Emsland Stärke introduced its quality and hygiene management in 2001.

In the following years, Emsland-Stärke formed a global distribution network. Representative offices were founded in Asia, the USA and Turkey.

The entire material and goods flow is coordinated by Emsland-Stärke Logistics GmbH & Co. KG, a 100 % subsidiary of Emsland-Stärke.

Expansion of product range to include pea starch / New research laboratory

In addition to the raw material of potatoes, processing peas also began in 2004 at Emlichheim. This resulted in the Emsland-Stärke establishing a second foothold and expanding the product range to include pea starch and pea protein and pea isolate byproducts. In addition, the production of nutritional fiber based on peas was added in the years to follow.

Emsland-Stärke also received the matrix certification according to DIN EN ISO 9001:2000.

As a global company, Emsland-Stärke and all its subsidiaries have since been represented together as pioneers under the Emsland Group umbrella name with the international slogan “using nature to create”. The focus on quality at the highest level is consistently visualized and communicated externally.

In 2006, the research laboratory was converted and rebuilt for around 1 million euro to fulfill the prerequisites for specific, application-oriented development.

Ubiquitous representation at the Food Ingredients Europe

The Emsland Group is constantly striving to be represented as far and wide as possible, which resulted in the successful participation at Food Ingredients Europe. In the coming years, the Emsland Group is planning to participate in trade fairs in mainly the field of food.

Company start-ups and joint ventures

In October 2006, the new company Emsland-Aller Aqua was founded. This company was created through a joint venture between the Danish company Aller Aqua Technology AS and Emsland-Stärke GmbH. They develop and produce fish feed and other animal feed based on proteins. The company has Europe’s most modern fish-feed factory in Golßen, which opened on September 03, 2008.

In 2007, the joint venture with Healy Chemicals UK Ltd. was added, having 50 % shares in the Emsland Group. The potato starch plant in Wietzendorf, which had been leased since 1986, was bought by the Emsland Group in 2008.

Quality and hygiene management and new liquid adhesive plant

In 2009, quality and hygiene management was merged with the areas of environmental management, occupational safety as well as health and energy management to create an “integrated management system”. Certification for the environmental management system was created according toDIN EN ISO 14001 as a result of this.

Climate protection is an important issue at the Emsland Group. Therefore, an energy supply at the Emsland Group that is geared toward the future is made possible by a new bioenergy power plant at the Emlichheim site. This is used for securing the energy supply and reducing energy costs.

At the end of March 2009, the new liquid adhesive facility for producing adhesives for the packaging market went into operation at the main plant in Emlichheim.

Main shareholder of Mecklenburger Kartoffelveredlung GmbH

At the beginning of the new 2013/2014 fiscal year, Emsland-Stärke GmbH in Emlichheim – a company of the Emsland Group – became the main shareholder of Mecklenburg Kartoffelveredlung GmbH in Hagenow. With its three plants, Emsland Food GmbH is the European market leader for producing dried potato products.

This is followed by a relaunch of the “Mecklenburger Küche” brand.

Opening of the Innovation Center in Emlichheim

In 2014, Emsland puts Germany’s first straw thermal power plant into operation with the BEKW bioenergy power plant. The main customer is Emsland-Stärke GmbH.

On October 29, 2014, the gates to the new innovation center open at the Emlichheim plant. The “Emsland Innovation Germany” research and development center is the linchpin for innovative development throughout the entire Group and is also a focal point for the many national and international contacts. The innovation center is where the globally active Emsland Group connects its nearby locations with its branches from around the globe to establish creative and productive exchanges. All ideas and innovations are in line with the guiding principle “using nature to create”.

Also in 2014, the company opened Emsland Asia Food Innovation in Bangkok, Thailand.

Additional potato receiving area

The commissioning of the new flake production line coincided with the 2014/2015 potato campaign. A new potato receiving area was added as part of the new plant access way. It will be used explicitly for the food sector and will meet the applicable food standards. This will allow the potatoes to be delivered, stored and processed separately. This, along with the production from Cloppenburg and Hagenow, will allow the Emsland Group to enter its next campaign with additional strength and as the world’s largest potato flake producer.

Into the future with a new logo

The Emsland Group began the year 2015 with a new logo. As a professional supplier of solutions in the area of food innovation, retail and food service, technical specialties and pet food, the Emsland Group has become established worldwide. The individual and creative product range, comprehensive expertise and customer-oriented service has laid a solid foundation for the coming years.

A global company has been made out of the once small potato factory and shaped by the company’s philosophy “using nature to create”. Raw materials are processed into innovative, trendsetting quality products in tune with nature. The most important raw material in this case is the potato, the starch of which is the basis for the Group’s success. Due to its individual and creative range of products, expertise and customer-oriented service, the Emsland Group has established itself on the world market and is not only Germany’s largest producer of potato starch, but is also a global leader in the production of refined starch products, proteins, fibers, potato flakes and granules.

New dextrin plant at the Kyritz mill

The commissioning of the new dextrin plant at the Kyritz site took place in February 2020 after a construction period of only eight months. In addition to the plant, a line was added to the big bag bagging facility, which was also commissioned. Thus, one of the latest technologies as well as a fully automated process moved into our Kyritz plant.

New dumpling granulate plant at the Hagenow site.

After four new roller dryers were already built in 2019 as part of a new flake plant at the Hagenow site, an additional plant was now added for the potato granules to be processed. With the installation of four new roller dryers, the Emsland Group once again underlines its leading position in the field of potato flakes and thus in the snack sector worldwide.

New skyline in Emlichheim

The Emsland Group has completed the construction of a 750 square meter production building that is over 33 meters high and includes new roller drying equipment and autoclaves. The new plant, which is nicknamed “WaltrAut”, was designed for the production of plant-based products for the building additives industry such as wallpaper paste, tile adhesives, starch ethers and environmental products.

In the production complex, more than 60,000 tons of potatoes from about 1,400 hectares of arable land, which is equivalent to the area of around 2,000 soccer fields, are processed into starch specialty products every year. To test the new plant, more than 500 tons of saleable products have already been successfully produced. The products are continuously tested in the Research & Development Department and scaled to large-scale production during the test phase. Testing for the final production is scheduled for January/February 2022. The plant is expected to be fully operational and in operation 24/7 by the spring of 2022, and the commissioning and optimization phases will be completed in the summer.

The investment in WaltrAut is the start of a long-term investment offensive by the Emsland Group called EmVision 2030. The final production tests were scheduled for January/February 2022. The plant has been fully operational since spring 2022, with the commissioning and optimization phase completed the following summer.

Let’s talk!

You have questions? We answer them.

Do you have any questions remaining one of our high-quality potato products, the Emsland Group or your career opportunities in our company? Then feel free to contact us via our contact form. We will get back to you promptly.